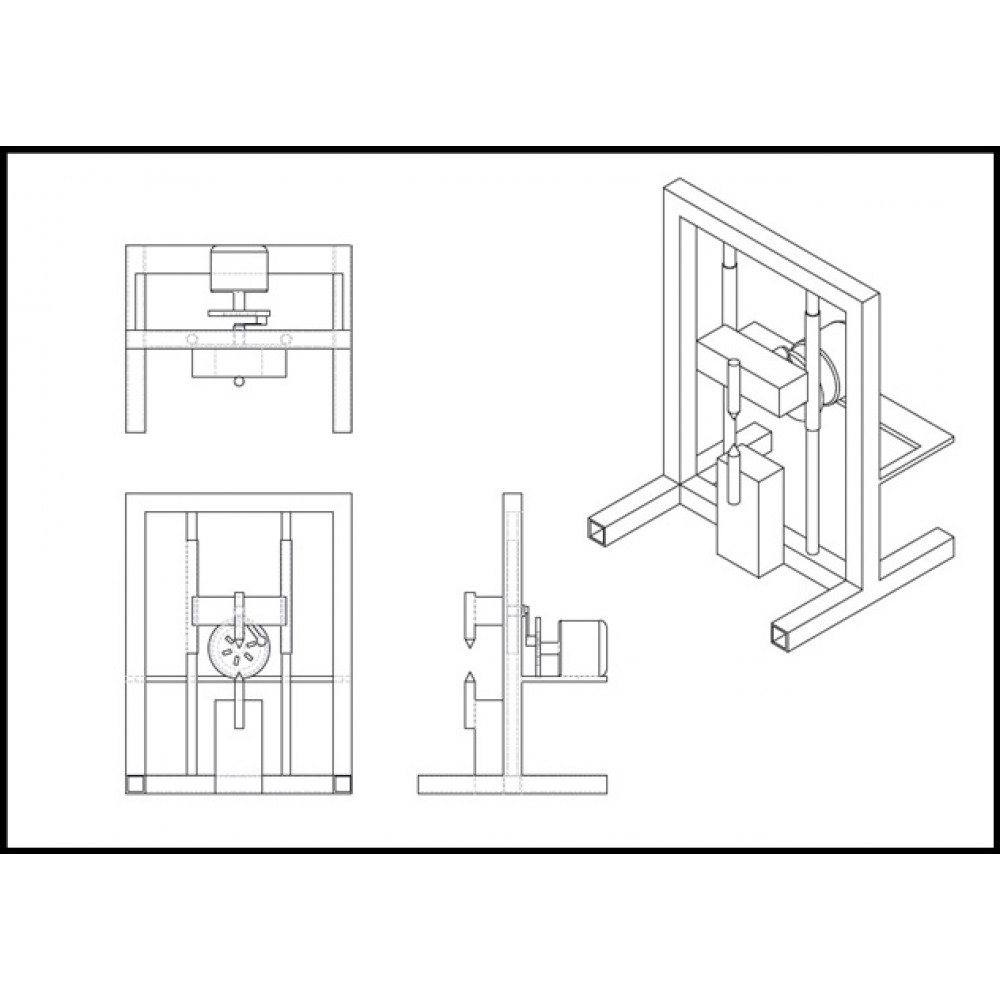

Automatic Spot Welding Machine

- Blog

- Discount New Year

- Final Year Matlab Proj

- final year proj

- Final Year Proj for Computer Science

- Final Year Proj for Electronics

- Final Year Proj for Information Technology

- Mini Projects

- Order cancellation

- Privacy policy

- Project Categories

- Return Policy

- Terms and Conditions

- Terms of use

- Tutorials

- Discount

-

Projects

- Embedded

- Java

-

Matlab

- 5G Communication/Signal Processing

- ANTENNA Design

- Artificial intelligence

- Automation & Fault Detection

- Cryptography- Authentication

- Cyber Security

- Data Analytics

- Deep Learning

- Digital Image Processing

- GAN

- Machine Learning

- Matlab Hardware Interface

- Medical Imaging

- Natural Language Processing

- Robotic OS (ROS) - Hardware

- Robotic OS (ROS) - Simulation

- Web Application

- Mechanical

- Python

- VLSI

- Workshops

- Internship

Your shopping cart is empty!

Product Description

Aim:

The main stay of the project is to design, mechanize and fabrication of an automatic spot welding machine powered by electric motor.

Proposed System:

Here we are going to create an automatic spot welding machine which is powered by an electric motor. It has a welding equipment attached to a slider which moves up and down, when two pieces of sheet metal is placed when the slider is up and when slider comes down it will spot weld both the sheet metal.

Advantages:

- In this type of welding the base metal does not undergo to large heat affected area.

- This type of welding is a easy process.

- Spot welding has a high production rate.

- Spot welding can be applied to different metals to join.

- Spot welding is a low-cost process.

Abstract:

A Virtual Machine has led to a fully automatic spot welding system. All necessary parameters are created by measuring systems and algorithms running in the Virtual Machine. A hybrid operating circuit allows the Virtual Machine to read the exact process voltage between the tips of the electrodes every 50 μs. Actual welding voltage and current allow for the first time reading process impedance, electric power and total energy being transferred to the spot weld. Necessary energy input is calculated by a calorimetric model after measuring the total thickness of the materials to be welded as soon as the welding gun is positioned at the workpiece.

A precision potentiometer implemented in the gun delivers the total material thickness within the 0.1 mm range during the pre-pressure phases. The internal databank of the Virtual Machine controls all essential parameters to guide the total welding process. Special generator characteristics of the welding power unit are created by the Virtual Machine just during the upslope and the welding phases. So the process will be initialized in differentiating the kind of material, mild steel or high strengthen steel. This will affect the kind of energy input and current decrease during the upslope and downslope phases.

When you order from finalyearprojects.in, you will receive a confirmation email. Once your order is shipped, you will be emailed the tracking information for your order's shipment. You can choose your preferred shipping method on the Order Information page during the checkout process.

The total time it takes to receive your order is shown below:

The total delivery time is calculated from the time your order is placed until the time it is delivered to you. Total delivery time is broken down into processing time and shipping time.

Processing time: The time it takes to prepare your item(s) to ship from our warehouse. This includes preparing your items, performing quality checks, and packing for shipment.

Shipping time: The time for your item(s) to tarvel from our warehouse to your destination.

Shipping from your local warehouse is significantly faster. Some charges may apply.

In addition, the transit time depends on where you're located and where your package comes from. If you want to know more information, please contact the customer service. We will settle your problem as soon as possible. Enjoy shopping!

Download Abstract

Click the below button to download the abstract.

Package Includes

Software Projects Includes

- Demo Video

- Abstract

- Base paper

- Full Project PPT

- UML Diagrams

- SRS

- Source Code

- Screen Shots

- Software Links

- Reference Papers

- Full Project Documentation

- Online support

The Delivery time for software projects is 2 -3 working days. Some of the software projects will require Hardware interface. Please go through the hardware Requirements in the abstract carefully. The Hardware will take 7-8 Working Days

Hardware Projects Includes

- Demo Video

- Abstract

- Base paper

- Full Project PPT

- Datasheets

- Circuit Diagrams

- Source Code

- Screen Shots & Photos

- Software Links

- Reference Papers

- Lit survey

- Full Project Documentation

- Online support

The Delivery time for Hardware

projects is 7-8 working days.

Mini Projects: Software Includes

- Demo Video

- Abstract

- Base paper

- Full Project PPT

- UML Diagrams

- SRS

- Source Code

- Screen Shots

- Software Links

- Reference Papers

- Full Project Documentation

- Online support

The

Delivery time for software Miniprojects is 2 -3 working days.

Mini Projects - Hardware includes

- Demo Video

- Abstract

- PPT

- Datasheets

- Circuit Diagrams

- Source Code

- Screen Shots & Photos

- Software Links

- Reference Papers

- Full Project Documentation

- Online

support

The Delivery time for Hardware Mini projects is 7-8 working days.